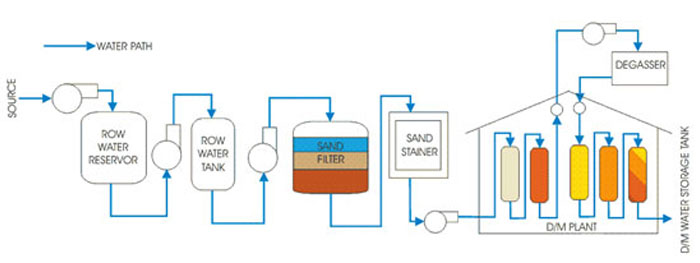

Demineralization Plant

The demineralization is the process of removing mineral salts from water by using ion exchange process. The D.M water reduces the scale formation, Deposition and corrosion of tubes. It increases the life of pipes and tubes in plant. It prevents the deposition of minerals in turbine blades. It removes Mineral salts in the form of cations such as sodium, calcium, iron, copper and anions such as chloride, sulphate , nitrate etc.

Among other things, they are used in hospitals and laboratories as well as in the production of process water, water for steam boilers and high-pressure hot water boilers, and cooling water.

The plants are of packaged modular design which gives competitive prices. TVPL’s standard range of products covers most requirements. The plants have a simple structure, are easy to operate, and the design is corrosion-resistant and compact. Frame-mounted plants are easy and quick to install.

Flow rates for standard modules: Up to 50 m³/h. Demineralization plants are produced as automatic, two-tank plants (co-currently and countercurrently regenerated) and mixed-bed plants in which the regeneration either takes place on site or on the basis of service. Mixed-bed is frequently used where stringent requirements for low contents of salt and silica apply.

Sources of Water

There are 3 types of sources of water-

1. Surface water ---- River water,lake water, pond water ect.

2. Ground water ---- Bore water, well water.

3. Sea water ---- Sea water.

Rain water is the purist of all sources of water. since the water having unique property of absorbing every thing on the earth that is why water is called universal solution. As the rain water falls on the earth it will be exposed with several gases present in the atmosphere, after falling on the earth water will be flows through several salts& minerals on the earth. In this way water is getting contaminated.